Process Flow of Precision Sheet Metal

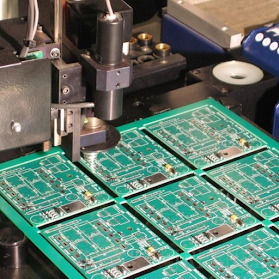

The sheet metal processing technology is complex and diverse, mainly including cutting, blanking, bending, etc. At the same time, it also provides services such as laser cutting, spraying screen printing, and assembly according to the customer's drawing design requirements. The following is the basic process of JR Sheet Metal Processing. 1.Material Application. According to the order, the engineer calculates the size and type of the required raw materials, and applies to the warehouse for requisition for subsequent product production. 2. Blanking. Technical engineers design according to customer drawings, decompose and expand all parts graphics. According to the size and thickness of the material, the workers use shears/laser cutting and other equipment to cut from large plates to obtain materials of appropriate sizes for each part. If it is a batch order, the punch die can be customized and die-cut directly into the unfolded figure of the part.When doing the blanking of this