The Function and Classification of PCB Terminal

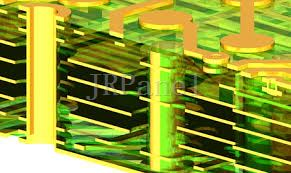

Terminal: It is a relatively basic accessory used to realize electrical connection, and it is also a fixed part of the terminal or connection between connecting wires, electrical appliances and control boards. PCB Terminal: Generally speaking, it is a kind of accessory product for PCB to realize electrical connection, which is divided into the category of connector in industry. In addition, the PCB terminal has some other names: because its shape is generally in a row shape, it is also known as wiring block, terminal block, wiring board and so on. The function of PCB terminal is to ensure the electrical connection is firm, safe and beautiful, and to improve the convenience of electrical installation and maintenance. Generally speaking, PCB terminal can be divided into the following types: 1. PCB Plug-in Terminal It consists of two parts plug-in connection, one part presses the wire tightly, and then plugs into the other part, this part is soldered to the PCB board, suitable for aut