The Importance of Predictability for High-end PCB Manufacturing

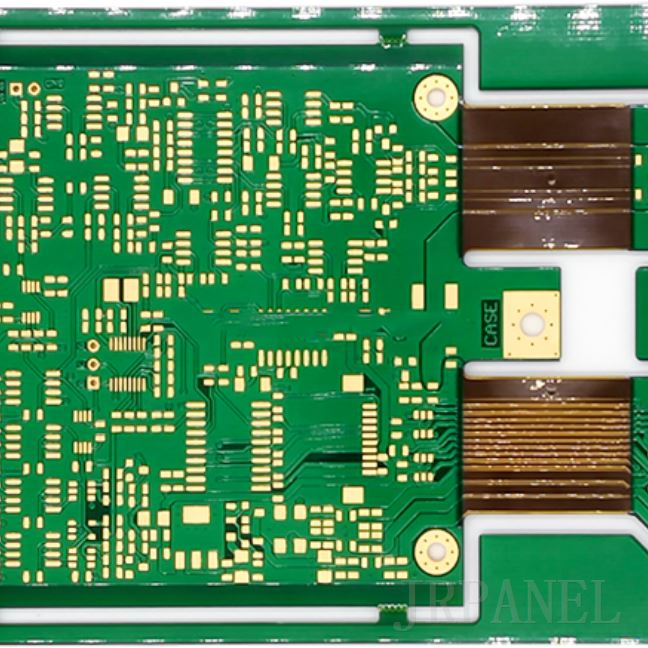

If there is a way to ensure that the product is reliable, it is to ensure the predictability of its PCB, which is an important part of the product. In fact, PCB is the core component in almost all electronic products (from phones to computer systems) today. From automobiles to national defense, from aviation to technology, PCBs are ubiquitous in any industry.

In all these industries, product reliability is of paramount importance. Whether it is medical technology or aviation technology, any mistake can cause huge losses. Similarly, in the medical field, equipment failure can have terrible consequences, leading to loss of life.

This requires rewriting the traditional predictability method. Traditional predictability methods are usually based on physical inspection. However, physical inspection has inherent disadvantages, that is, only external defects can be inspected. Another problem faced by physical inspection is that when the PCB is complex and has countless vias, microsectioning and inspection become a logistical nightmare. If only a few vias are checked, the process will be foolproof. Due to the high diversity of products, traditional statistical tools are not enough to find defects.

Therefore, for PCBs with high complexity and product diversity, the predictability that traditional inspection cannot guarantee becomes particularly important.

The solution to this problem is to use extremely comprehensive data analysis, test automation and digitization. It is comprehensive statistical information that can lead to reliability and traceability. With the help of powerful data, predictions can be made accurately. Any abnormal behavior can be eliminated, and atypical products can be eliminated.

What this essentially requires is that all available data is stored in a centralized manner. In fact, every machine needs to be programmed with an interface in order to load all the data into the centralized warehouse. In turn, this allows for in-depth data analysis. It can also ensure that, unlike the physical inspection process, correlation is made in the event of a failure. But even so, there are challenges because the data is obtained from multiple sources and converted into countless data points. This problem can be solved by formalizing the two-stage data processing format. The first stage is to standardize the data, and the second stage is to analyze the standardized data. Scientific data analysis means that you don't have to rely on finding problems to respond after the manufacturing process is over. Rather, it allows you to proactively predict problems and ensure that the possibility of failure is minimized. This can be done because the process input variables can be controlled. In turn, what it controls is delay, which can cause great losses.

Even though predictability may be invaluable, the truth is that the cost of failure far exceeds that cost.

China PCB Manufacturer

回复删除