The Necessity and Importance of Membrane Switches Prototype

Today JRPanel would like to discuss with you about the necessity and importance of membrane switches prototype.

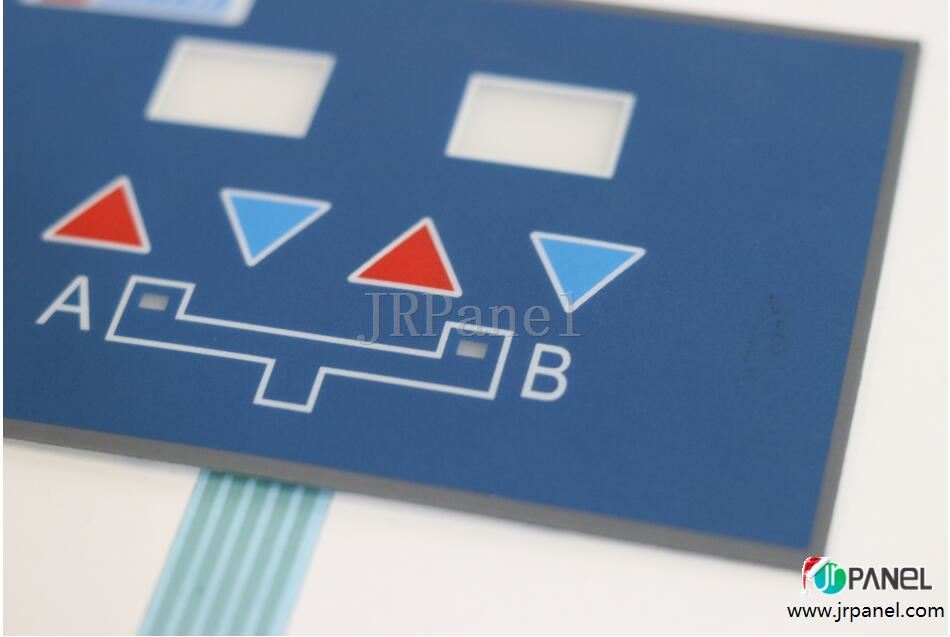

Prototypes are an important basis for the quality control of JRPanel membrane switches and a tool for communication with customers. Its functions are mainly reflected in the following two aspects.

First, the prototype can help customers check the various information contained in the document so that they can be modified in time, such as fonts, patterns, colors, etc. Color is the most difficult to control in prototype, because different panel materials and ink thinness will cause the color of the prototype to change.

Second, the prototype can be used as a contract between the customer and the membrane switch factory. The contract prototypes should accurately provide the same color as the final membrane switch, and the contract prototypes should be printed out shortly before mass production to avoid fading and distortion of the prototypes due to long storage time.

prototype is a process connecting pre-press production and printing, allowing users to foresee the effect of the final membrane switch before mass production. It can provide standards for the entire membrane switch production process and provide a strong guarantee for the improvement of the quality of membrane switches.

Two ways of prototype for membrane switches:

1. Soft prototype:

Soft prototype is realized on a color display, and it is undoubtedly the most convenient, fastest, and cheapest prototype method. The color display requires high accuracy and must be correctly calibrated. The obvious shortcomings of the soft prototype method are: the resolution is low, only 72dpi; the accuracy of the color depends on the performance and calibration of the display, and the metallic color cannot be accurately reflected.

2. Traditional prototype

It needs to output the film and make the silk print screen, and then complete the prototype on the screen printing machine.

The production process of traditional prototype prototype plate and mass production plate is the same. prototype and mass production use the same file data, and potential problems such as moiré, color, and font patterns can be found through prototype.

评论

发表评论